Conformal coating is a thin layer of polymer or synthetic resin used to protect electronic devices from environmental, mechanical, electrical and chemical problems. There are five basic types of conformal coatings: acrylic acid (type AR), epoxy (type ER), organic silicone (type SR), parylene (type XY), polyurethane (type UR). Different materials have different characteristics, and customers choose a protective coating suitable for their products according to different places of use and methods of use.

The Parylene deposit uses a special vacuum coating equipment. The deposition process is the first step of evaporating the raw material at a temperature of about 150 ° C. The second step is to crack the two side chain carbon-carbon chains at 680 ° C to form a stable active monomer. Finally, the active monomer enters the deposition chamber at room temperature for polymerization deposition, and is instantaneously adsorbed on the substrate to be polymerized into a Parylene filmParylene.

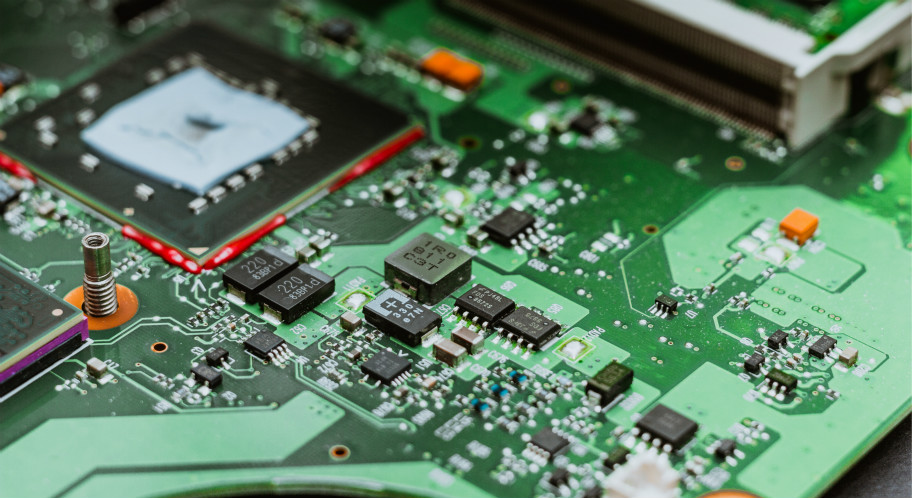

Parylene is a conformal coating material prepared by a unique vacuum vapor deposition process that "grows" a fully conformable polymer film coating from the active small molecules on the surface of the substrate. It can be coated on a variety of surfaces, including sharp edges, cracks, inner surfaces and can be penetrated into the inner crack and inner surface. Uniform coating thickness, compact pinhole-free, transparent and stress-free, no additives, no damage to the product, excellent electrical insulation and protection, is the most effective moisture-proof, mold-proof (zero-grade), anti-corrosion coating material.

Parylene has many advantages over other conformal coatings. This vacuum-based micron film coating can achieve excellent electrical insulation and barrier properties, surface hydrophobicity, lubrication, and good biocompatibility, thermal stability, etc. Parylene is particularly suitable for the protection of high-frequency components, because the existing conformal coatings such as epoxy, polyurethane and acrylic acid will have a greater impact on the microwave performance of high-frequency components.。